Performance and Efficiency of Servo Hydraulic Power Units #

The Servo Hydraulic Power Unit is engineered to deliver high efficiency and reliability for demanding industrial applications. This unit stands out due to its innovative design, energy-saving features, and robust performance metrics.

Key Features #

- Universal Frequency Compatibility: Operates identically at both 50Hz and 60Hz.

- Low Power Consumption: Utilizes only 0.75 kW during operation.

- Efficient Pressure Maintenance: Requires just 120 rpm to maintain pressure.

- Rapid Acceleration: Achieves a speed increase from 120 rpm to 2000 rpm in only 0.01 seconds.

- Energy Efficiency: Especially suitable for large machinery, offering significant energy savings.

- Minimal Temperature Rise: The system maintains a low operational temperature, eliminating the need for additional fluid cooling.

Feature Highlights #

- Low Fuel Tank Temperature Rise: Fuel temperature increases by only 5°C during operation.

- Low Noise Operation: Standby noise levels remain under 60 dB.

- Fast Response Time: Accelerates from 120 rpm to 2000 rpm in just 0.01 seconds.

- Minimal Vibration: Vibration remains under 5μ during standby.

- Reduced Electricity Consumption: Consumes only 0.16 kWh.

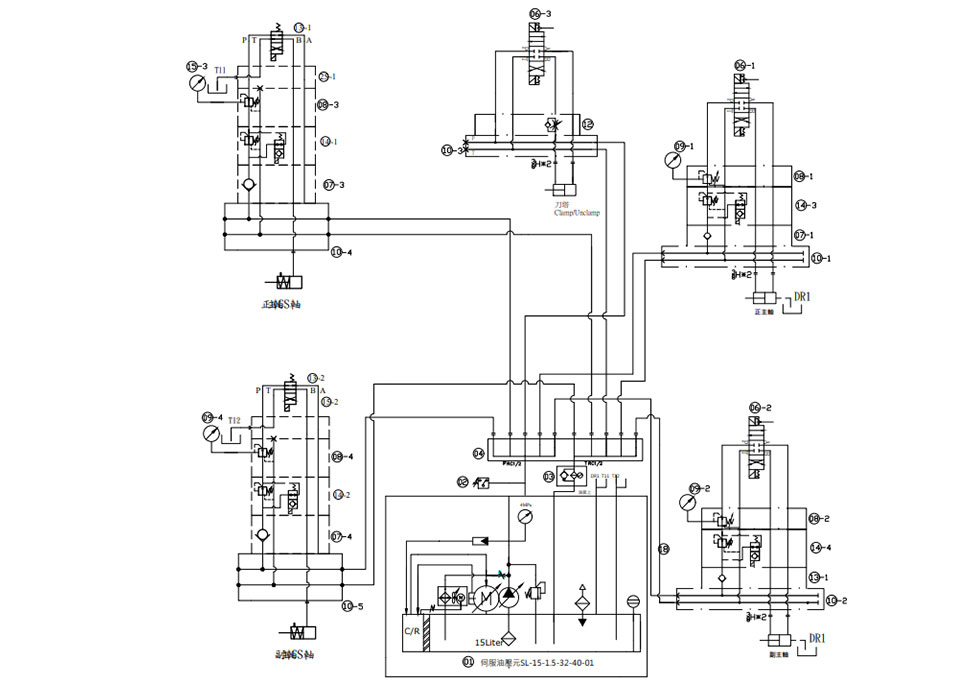

Circuit Diagram #

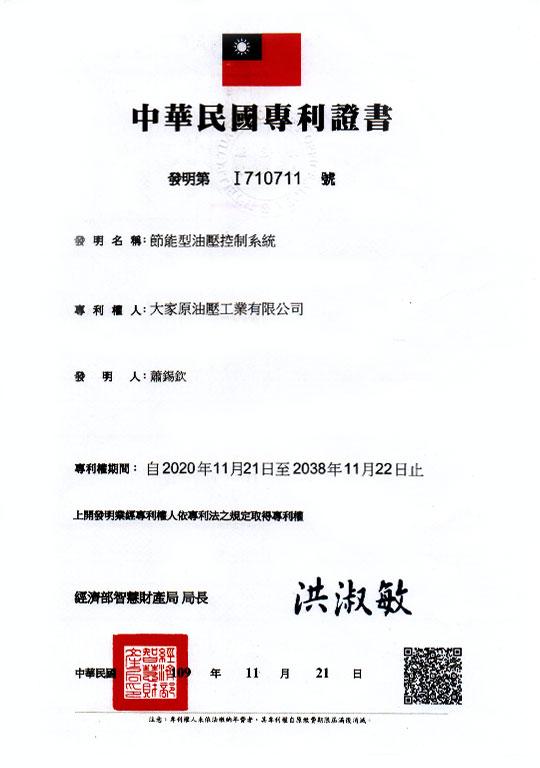

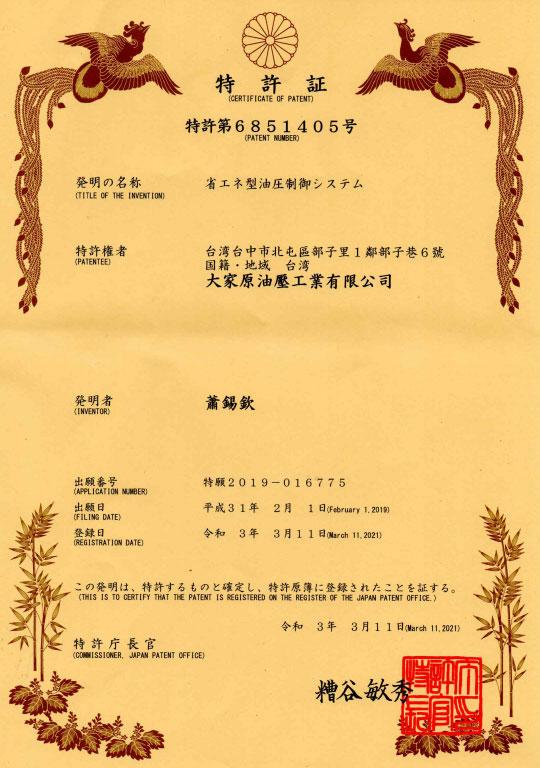

Patents #

The AnyPower servo hydraulic system holds patents in both Japan and Taiwan, underscoring its unique design and technological innovation.

Comparative Analysis #

AnyPower Servo Power Unit vs. Vane Pump Power Unit #

| Item | AnyPower Servo Power Unit | Vane Pump Power Unit |

|---|---|---|

| Power consumption per hour | 0.14 kWh | 0.7 kWh |

| Room Temperature | 29°C | 28°C |

| Fluid Temperature | 30°C | 39°C |

| Rise of Temperature | 1°C | 11°C |

| Motor Temperature | 34°C | 45°C |

| Pump Temperature | 31°C | 45°C |

| Vibration | 1.3μ | 3.5μ |

| SPL | 53 dB | 70 dB |

| Current value R | 0.43A | 2.92A |

| Current value S | 0.20A | 2.55A |

| Current value T | 0.32A | 2.90A |

The servo hydraulic unit saves 79% more energy than the vane type hydraulic unit.

Servo Power Unit vs. Piston Pump Power Unit #

| Item | Servo Power Unit | Piston Pump Power Unit |

|---|---|---|

| Power consumption (holding) | 0.12 kWh/h | 0.52 kWh/h |

| Motor Format | 0.75 kW-10P | 1.5 kW-4P |

| Pump Discharge | 16 cc/rev | 16 cc/rev |

| Setting Pressure | 4.0 MPa | 4.0 MPa |

| Capacity of Tank | 15 Liter | 20 Liter |

| RPM (holding Pressure) | 120 rpm | 1440/1720 rpm |

| RPM (Rated) | 2000 rpm | 1440/1720 rpm |

| Rise of Temperature | Under 5°C | Under 10°C |

| SPL | Under 60 dB | Under 70 dB |

| Vibration | 3μ | Under 5μ |

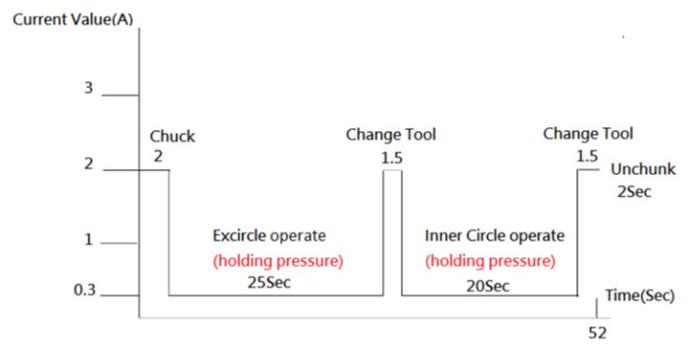

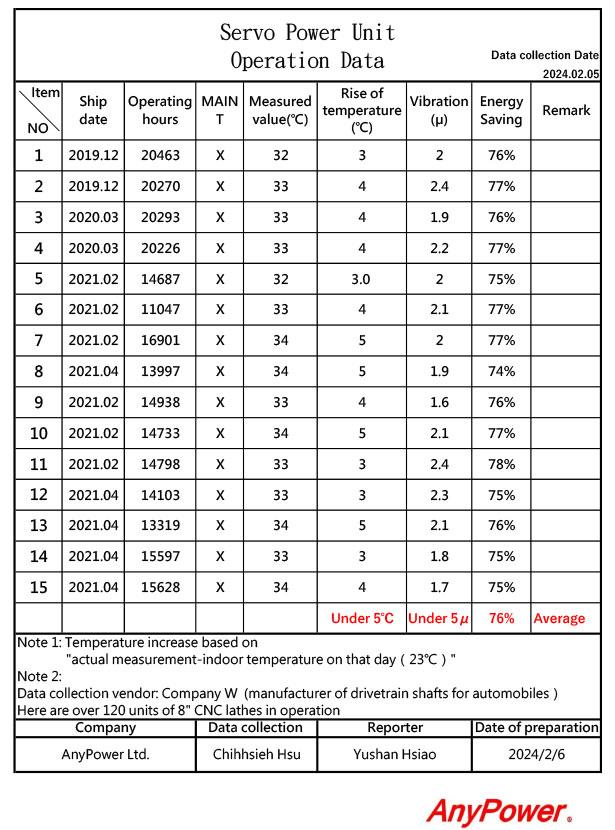

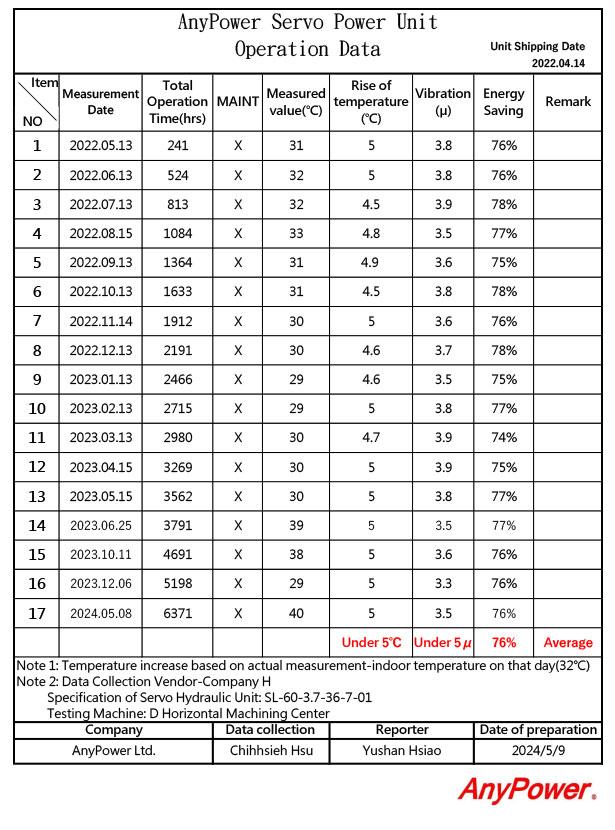

Operational Testing Results #

- Testing Period: March 1, 2018, 1 pm – September 6, 2018, 11 am

- Total Operating Hours: 4,088 hours

- Total Power Consumption: 665.8 kWh (0.163 kWh per hour)

24-hour Operation Test (Monday to Saturday)

- Produces 1 component every 52 seconds

- Average: 48 components per hour

- Power consumption: Servo hydraulic unit uses 0.16 kWh, piston type uses 0.68 kWh

Conclusion: The servo hydraulic unit achieves a 76% energy saving compared to the piston type hydraulic unit.

For further information or specific inquiries, please contact the manufacturer directly.