Modernizing CNC Lathe Hydraulics for Efficiency and Precision #

CNC lathes rely on hydraulic power packs to perform essential operations such as clamping workpieces with chucks and tailstocks, executing rapid and precise turret tool changes, and ensuring reliable spindle braking. These hydraulic functions are integral to machining accuracy, operational efficiency, and workplace safety.

Challenges with Conventional Hydraulic Systems #

Traditional hydraulic systems in CNC lathes present several limitations:

- Continuous Pump Operation: Conventional setups keep the hydraulic pump running at all times, even when chucks and tailstocks do not require constant pressure. This results in unnecessary energy consumption.

- Pressure Instability: During workholding and turret tool changes, CNC machines demand quick, high-pressure surges. Traditional hydraulic units often cannot respond rapidly, leading to pressure drops that compromise machining accuracy.

- Overheating: Prolonged operation generates excess heat, which degrades hydraulic oil and reduces system stability, ultimately affecting machining precision.

Advantages of Upgrading to Servo Hydraulic Systems #

Switching to an AnyPower Servo Hydraulic System addresses these challenges with notable benefits:

- On-Demand Pressure Supply: Pressure is delivered only when needed, eliminating energy waste during idle periods.

- Rapid Response: With a response time as fast as 0.01 seconds, pressure drops are minimized, supporting higher machining accuracy.

- Reduced Overheating: The system avoids continuous operation, which helps maintain stable hydraulic oil temperatures and preserves machining precision.

Application Case Studies #

Company W: Automotive Transmission Shaft Production #

-

Background:

- Factory with over 120 CNC lathes dedicated to transmission shaft processing

- From 2019 to 2021, 15 Anypower servo hydraulic units were installed

-

Performance:

- Each unit has operated for over 10,000 hours without maintenance

- Despite a higher initial investment, energy savings have already offset the cost

- Zero maintenance translates to zero service expenses

-

Measured Results:

- Testing period: March 1, 2018 to September 6, 2018 (4,088 hours total)

- Total power consumption: 665.8 kWh (0.163 kWh per hour)

- 24-hour operation test (Monday to Saturday):

- Produces 1 component every 52 seconds, averaging 48 components per hour

- Servo hydraulic unit: 0.16 kWh per hour

- Piston-type hydraulic unit: 0.68 kWh per hour

- Conclusion: Servo hydraulic units achieve a 76% energy saving compared to piston-type units

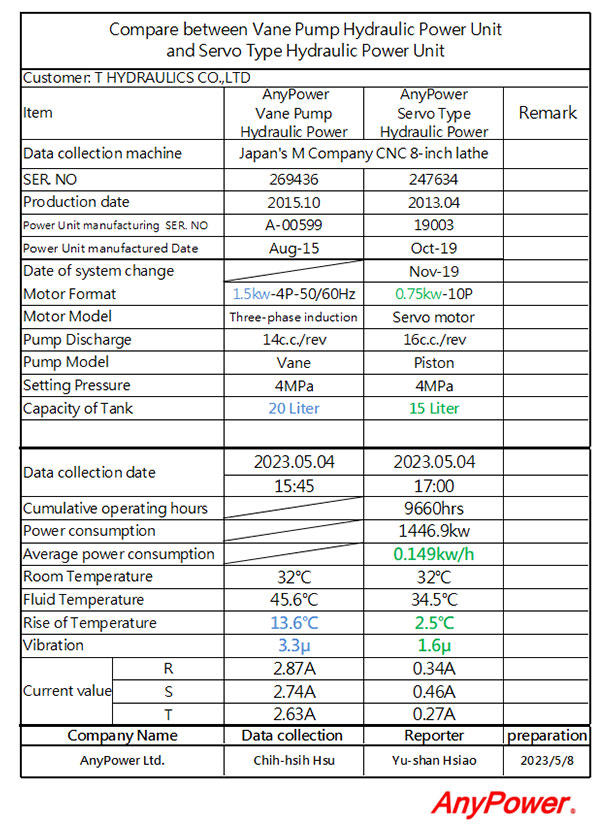

Company P: Japanese Machine Tool Integration #

-

Background:

- Company P purchased two machines from Japan’s Company M

- Both originally featured traditional hydraulic units; one was upgraded to an AnyPower servo hydraulic unit in 2019

-

Performance Improvements:

- Hydraulic tank size reduced from 20L to 15L

- Motor power reduced from 2HP to 1HP

- Notable reductions in temperature rise, noise, and vibration

- No maintenance required since installation

- Energy-saving efficiency reached 79%

-

Comparison Table:

Item AnyPower Servo Power Unit Vane Pump Power Unit Power consumption per hour 0.14 kWh 0.7 kWh Room Temperature 29℃ 28℃ Fluid Temperature 30℃ 39℃ Rise of Temperature 1℃ 11℃ Motor Temperature 34℃ 45℃ Pump Temperature 31℃ 45℃ Vibration 1.3μ 3.5μ SPL 53 dB 70 dB Current value R 0.43A 2.92A Current value S 0.20A 2.55A Current value T 0.32A 2.90A Result: Servo hydraulic unit saves 79% energy compared to vane-type hydraulic units.

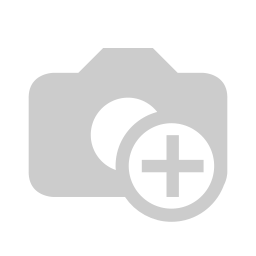

Servo Hydraulic Power unit

Servo Hydraulic Power unit Piston Pump Power Unit

Piston Pump Power Unit Hydraulic Spare Parts

Hydraulic Spare Parts